Stainless steel is an alloy of steel that contains a minimum of 10.5% chromium, which gives it unique properties of resistance to corrosion and rust. This combination of metals significantly enhances the material’s durability compared to carbon steel, which tends to rust easily when exposed to moisture and chemicals.

Chromium forms a layer of chromium oxide on the steel’s surface, which acts as a protective barrier against corrosion. In addition to its corrosion resistance, stainless steel also offers high resistance to heat and high temperatures, making it ideal for applications in extreme environments. For this reason, it is frequently used in the chemical and petrochemical industries, as well as in the manufacturing of furnaces and thermal processing equipment. Its ability to maintain its structural properties even at high temperatures makes it a reliable choice for demanding industrial applications.

Chromium forms a layer of chromium oxide on the steel’s surface, which acts as a protective barrier against corrosion. In addition to its corrosion resistance, stainless steel also offers high resistance to heat and high temperatures, making it ideal for applications in extreme environments. For this reason, it is frequently used in the chemical and petrochemical industries, as well as in the manufacturing of furnaces and thermal processing equipment. Its ability to maintain its structural properties even at high temperatures makes it a reliable choice for demanding industrial applications.

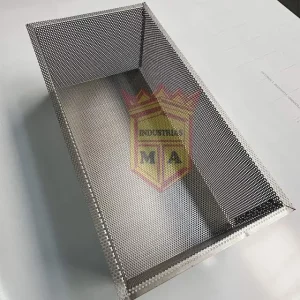

Stainless steel is widely used in the food and medical industries due to its ease of cleaning and resistance to germs and bacteria. In the manufacture of kitchen utensils, food processing equipment, and medical equipment, stainless steel ensures that products are hygienic and safe for use in environments where cleanliness and sterilization are crucial.

Stainless steel is widely used in the food and medical industries due to its ease of cleaning and resistance to germs and bacteria. In the manufacture of kitchen utensils, food processing equipment, and medical equipment, stainless steel ensures that products are hygienic and safe for use in environments where cleanliness and sterilization are crucial.

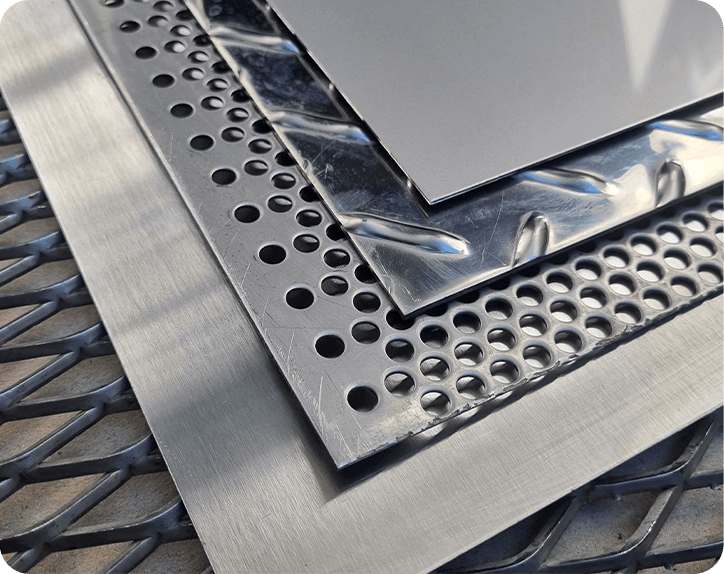

In the construction and architectural fields, stainless steel is employed in a variety of aesthetic and functional applications. Its shiny finish and weather resistance make it ideal for decorative elements, building facades, and handrails. Additionally, stainless steel contributes to durability and low maintenance in construction projects, as it does not require additional coatings or treatments to prevent corrosion.

In the construction and architectural fields, stainless steel is employed in a variety of aesthetic and functional applications. Its shiny finish and weather resistance make it ideal for decorative elements, building facades, and handrails. Additionally, stainless steel contributes to durability and low maintenance in construction projects, as it does not require additional coatings or treatments to prevent corrosion.